If the slack in your spindle is not tight enough you can use the video and directions below to fix it yourself.

To get started you will need to have access to the tether. You can disassemble your sensor by:

1) Take out the top screws with an Allen wrench

2) Use a USB cable to push down the charging port and pull up the case

3) Disconnect wires

4) Lift rest of unit from the base to access tether

*You can use the beginning of this video to show how to disassemble

Now hold, or have somebody hold the outer shell and rubber stopper so that you have room to open the unit and work on the inside. Take apart the wires connecting the PCB (green board) to the battery + the switch and keep the top plastic chassis (with the PCB) inside the outer housing. Now that you have eyes on the spindle and the bottom base, you will carefully unscrew the screw that keeps the axle in place. This is the axle:

After unscrewing the axle, take the screw off and place it to the side. Take the spindle and axle out of the unit and ensure that the tether is still tightly in place. To do this, place the tip of the screwdriver in the hole where the screw was and carefully wiggle back and forth while lifting the spindle. With the tip of the screwdriver still in place, spin counterclockwise two whole rotations.

In order for your 'counterclockwise' to be the same as our 'counterclockwise', the screwdriver-end of the axle must be pointing toward your body.

Then, ensure that the screwdriver stays in the hole to prevent releasing the tension and put the spindle and axle back in the base at the same position as earlier. Make sure that during this process, you are not allowing the spindle or axle to spin. If you do, it may cause the tether to still have slack or not have enough pre-tension.

After putting the spindle in the correct position, you should screw it back into place while firmly pressing the spindle down into the base to prevent the screw from lifting the axle while.

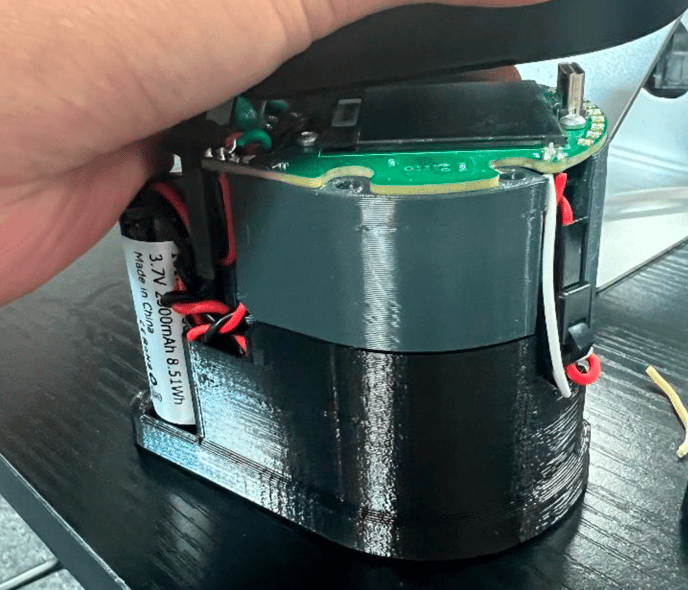

Now you can put the plastic chassis top back on and reconnect the wires between the PCB (green board) and the battery + switch. Put the wires inside the unit like so:

Now put the outer shell back on and see if the wire/tether still has slack. If not, great! :-)

If it still has some slack, try this process again, but instead of turning the axle 2x, do 3 rotations counterclockwise.

If the tether is impacting the functionality of your sensor you may be able to have it repaired if it is within warranty.

You can also look into our RepOne Protect Plan or purchase a one time repair.